Learn About Affordable Kitchen Appliance Clearance Sales

Outline:

– Retail clearance basics: what drives markdowns and how stores plan them

– Inventory turnover: the metric that explains why speed matters

– Product cycles: timing, refreshes, and the path to clearance

– Shopper tactics: reading signals, pricing ladders, and risk checks

– Conclusion and action plan: apply the insights to save money and avoid regret

Retail Clearance Basics: Why Products Get Marked Down

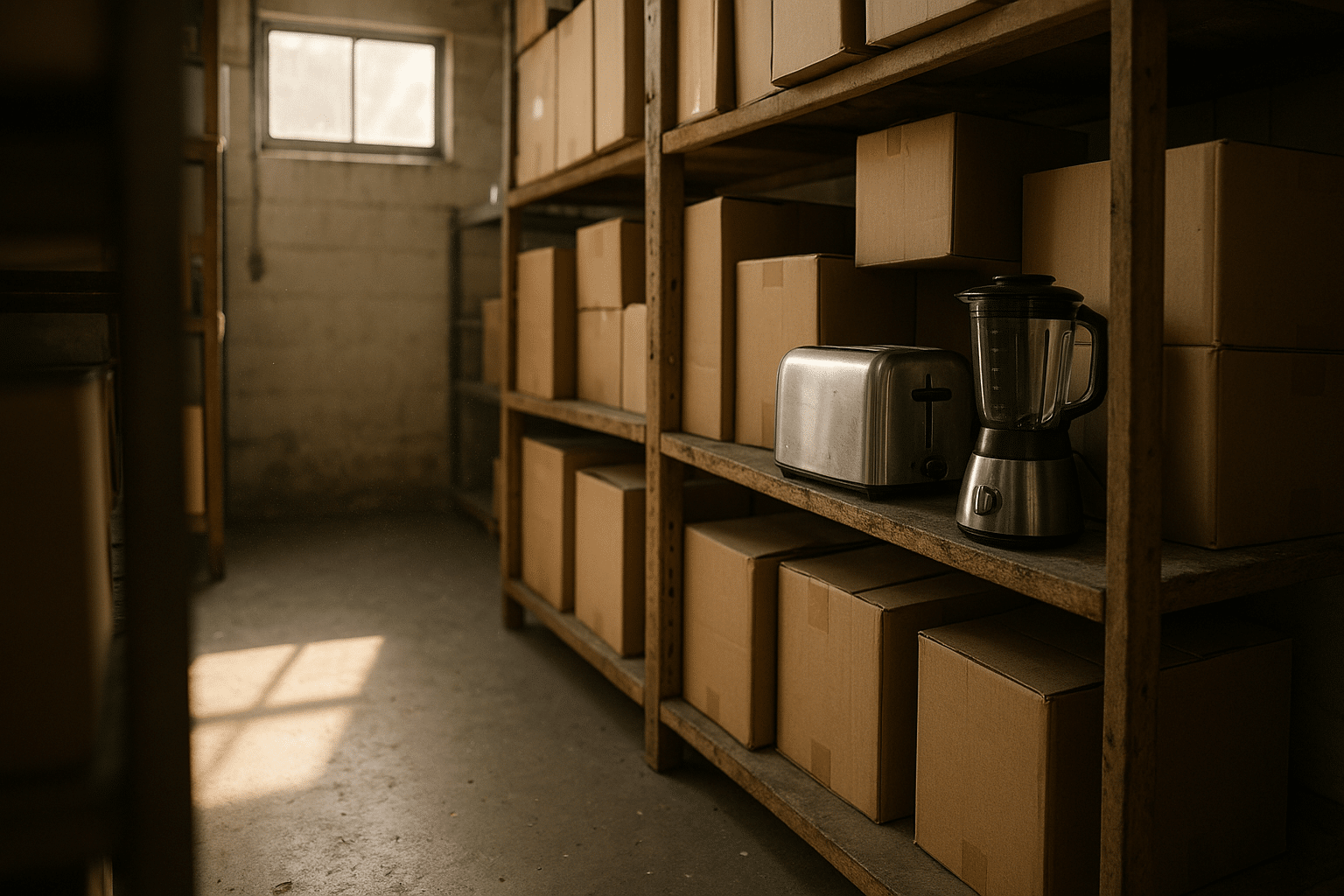

Clearance is not chaos; it is a planned system for turning space back into cash and making room for the next wave of products. Retailers use markdown ladders, promotional calendars, and floor resets to move items that are slow, seasonal, or approaching obsolescence. Kitchen appliances often enter clearance due to model updates or inventory rotation. The key drivers behind these decisions are both financial and operational: carrying costs accumulate, demand forecasts shift, and new assortments need shelf space. Rather than signaling poor quality, many clearances simply mark the end of a product’s planned life on the sales floor.

Several common clearance triggers appear across categories:

– Seasonality: bulky items give way to holiday or back-to-school sets, then pivot again in spring resets.

– Packaging changes: when a supplier updates packaging, the older version is discounted to avoid mixed displays.

– Feature refreshes: incremental upgrades make the prior edition a value play for price-sensitive buyers.

– Space constraints: stores cap the number of facings per category, pushing slower units into markdowns.

– Vendor terms and returns: negotiated allowances or exit deals can accelerate price reductions.

Markdowns often progress in steps. A typical ladder might start at 20–30% off to test demand, deepen to 40–50% as assortment changes lock in, and reach 60–70% for final clearance. Timelines vary by retailer, but the economics are consistent: the longer inventory sits, the more it costs. Consider a simplified example. If an item carries a cost of $70 with a retail price of $120, a store facing 20% annual carrying costs is incurring roughly 1.7% per month in storage, insurance, and opportunity costs. After three months, the added costs can outweigh a minor margin loss, making a 25–30% markdown rational. That is before accounting for floor congestion, labor to re-merchandise, and the opportunity to present new items that may yield higher gross profit dollars per square foot. Clearance, then, is a strategic tool: it preserves cash flow, improves the shopping experience, and keeps assortments fresh.

Inventory Turnover: The Metric Behind Clearance Decisions

Inventory turnover explains why some products are swiftly discounted while others hold full price longer. The core formula—turnover = cost of goods sold (COGS) divided by average inventory—measures how many times a retailer sells through its stock in a given period. A companion metric, days sales of inventory (DSI), equals 365 divided by turnover and shows how many days, on average, items stay in inventory. If a department records $1,200,000 in COGS with average inventory of $300,000, turnover is 4x; DSI is about 91 days. When DSI stretches far beyond the plan, managers face a choice: hold and hope for a demand bump, or mark down now and reinvest the cash.

Turnover targets vary by category. Fast-moving consumables can rotate in weeks, while durable goods may reasonably sit for months. The costs of slow turnover are tangible:

– Capital is tied up, restricting flexibility to buy newer, higher-margin items.

– Carrying costs accumulate (storage, insurance, shrink, and obsolescence risk).

– Space productivity declines as older items occupy premium shelf locations.

Conversely, healthy turnover brings benefits: predictable cash cycles, fewer aged units, clearer assortments, and smoother merchandising. Even modest improvements add up. Imagine reducing DSI from 100 to 80 days for a $500,000 average inventory position; that 20-day reduction frees roughly $27,400 in cash (500,000 x 20/365), providing fresh budget for promotions or expanded selection. Retailers act on these numbers with practical levers:

– Improve demand forecasting and align orders with realistic sell-through.

– Trim the long tail by rationalizing SKUs that rarely move or duplicate features.

– Use smaller, more frequent replenishment to reduce backstock.

– Coordinate vendor markdown allowances and exit programs to limit losses.

– Employ phased markdowns and targeted signage to accelerate sell-through without eroding the entire category’s price perception.

For shoppers, understanding turnover is a map to timing. Slow movers are likelier to appear on markdown ladders, especially as planograms reset. Items with bulky packaging or multi-box components are prime candidates for accelerated clearance if they strain stockrooms or complicate displays. Track the cadence: a first cut suggests testing demand; a second cut often signals a final push before the space is reassigned to new releases.

Product Cycles: How Launches, Refreshes, and Retirements Shape Clearance

Most consumer goods follow a recognizable arc: introduction, growth, maturity, and decline. In introduction, supply is tight and pricing is firm. Growth expands feature sets and variants, and maturity brings line extensions, colorways, and promotions. Decline begins when improvements elsewhere set a new standard or when the category’s design language shifts. At that point, clearance is not an afterthought; it is the planned bridge between the outgoing edition and incoming inventory. Kitchen appliances often enter clearance due to model updates or inventory rotation. That sentence captures a core retail reality: upgrade cycles are not random, and they connect directly to the markdown calendar.

Signs of a late-stage cycle include:

– Frequent promotional bundles and gift-with-purchase offers in preference to pure price cuts.

– Minor feature refreshes that maintain price points while preparing a full redesign.

– Packaging updates that standardize across the line, hinting at an imminent assortment reset.

The cadence of these transitions often syncs with major retail moments—early-year planogram resets, spring refreshes, back-to-school builds, and year-end holiday expansions. After peak seasons, stores compress assortments and clear slower variants, especially those with duplicate features or niche colors. The timing is pragmatic. Each square foot must produce a target number of gross profit dollars. When a new item is forecasted to outperform an aging model, the latter moves to markdown to unlock that space and cash. A helpful rule of thumb: when you see a full-bay display condense to a half-bay or endcap, the maturity stage is nearing its end, and deeper clearance is likely.

Shoppers can read these cues to calibrate patience versus urgency. If the new iteration only adds cosmetic tweaks, waiting for a larger markdown may pay off. If the upcoming redesign meaningfully upgrades performance or safety features, lingering too long risks missing out on a unit that meets specific needs at a solid price. Either way, recognizing the life-cycle stage transforms browsing into a deliberate choice rather than a gamble.

Smarter Shopping on the Clearance Aisle: Pricing Signals and Practical Tactics

Clearance strategy becomes actionable when you can interpret the signals on the shelf. First, learn the store’s markdown cadence. Some locations revise clearance tags on a fixed weekday; others adjust near the end of month or quarter. A first markdown suggests a test, a second implies commitment, and a final round is usually the last call before items are pulled for liquidation channels. Take notes on timing for two or three cycles, and you will anticipate the next adjustment with reasonable accuracy.

Second, weigh the total value, not only the sticker price. Look at warranty terms, parts availability, and the ease of service. If a unit is discontinued but shares components with current models, maintenance is less risky. When comparing tags, evaluate price-per-feature that matters to you rather than being distracted by extras you will not use. A simple worksheet helps:

– Identify three must-have functions and ignore nonessential add-ons.

– Calculate the effective price after likely next markdown (for example, expect a move from 30% to 50% within two weeks based on observed cadence).

– Factor in delivery or installation costs if applicable, and confirm return policy for clearance items.

Third, inspect condition with fresh eyes. Packaging scuffs are common and usually cosmetic. Check for:

– Complete accessories and manuals (an inventory slip or checklist inside the box can be helpful).

– Serial numbers or production dates to avoid very old stock if that matters to you.

– Evidence of prior returns, such as mismatched foam inserts or repacked wiring, which might warrant a further discount or a pass.

Finally, engage respectfully. Ask whether additional markdowns are scheduled or if the store honors competitor price matches on clearance—many do not, but policies sometimes allow flexibility. Consider bundling: pairing a clearance item with a full-price accessory can encourage a modest accommodation at checkout. Keep your goal specific, your tone friendly, and your timing aligned to the cadence you observed. This approach is among the most reliable paths to outstanding value without guesswork.

Conclusion: Turning Clearance Knowledge Into Confident Savings

Put the pieces together and clearance becomes predictable rather than mysterious. Start with the basics: stores mark down to unfreeze capital, raise space productivity, and prepare for new assortments. Use inventory turnover to understand urgency; high DSI often signals an impending price drop, while steady turnover supports full price. Read the product cycle to decide whether to wait for a deeper cut or act on a solid price today. Kitchen appliances often enter clearance due to model updates or inventory rotation. That reality means you can find strong value without compromising on quality, provided you scan for serviceability, missing parts, and realistic use cases.

Here is a compact action plan:

– Observe the markdown ladder over two cycles to anticipate the next cut.

– Verify warranty and parts support to reduce ownership risk.

– Prioritize must-have features and ignore cosmetic distractions.

– Inspect packaging and contents; negotiate politely if condition is imperfect.

– Time purchases around known reset periods when assortments contract.

For households shopping on a budget, these habits turn browsing into intentional savings. For small resellers or managers, the same principles guide exit decisions that protect margins and keep floors fresh. Clearance is not a compromise; it is a disciplined match between a product’s stage in life and a shopper’s needs. Approach it with a plan, and you will make clear-headed choices that respect your time, your space, and your money.